/Single%20Crush%20Aggregate..jpg?width=700&name=Single%20Crush%20Aggregate..jpg)

Aggregate (5-20MM)

Ksh850.00Aggregate (5-20MM)

We have been manufacturing building materials since 1952. Today, we are a leading supplier of quality construction materials and technical solutions. Over

the years, we have built up significant expertise and now have a fleet of over 100 trucks to ensure steady delivery to our esteemed clients. We have state-of

the-art quarry machinery and equipment to allow production of quality aggregates.

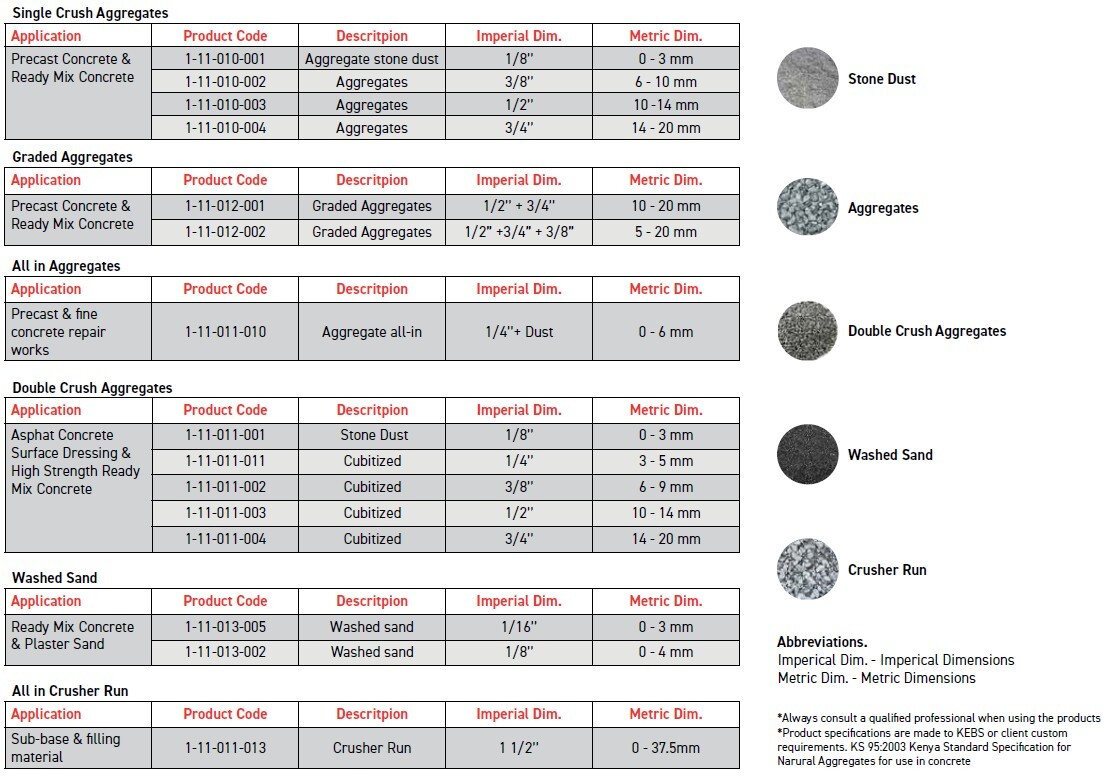

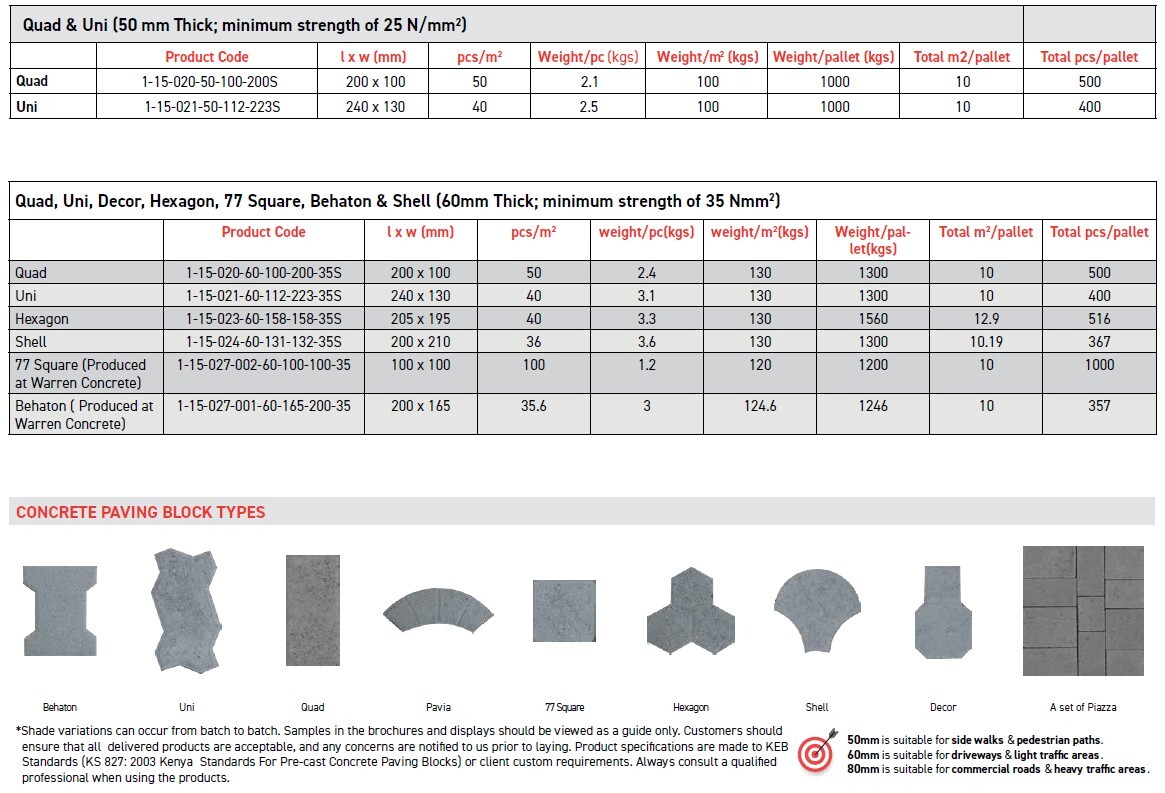

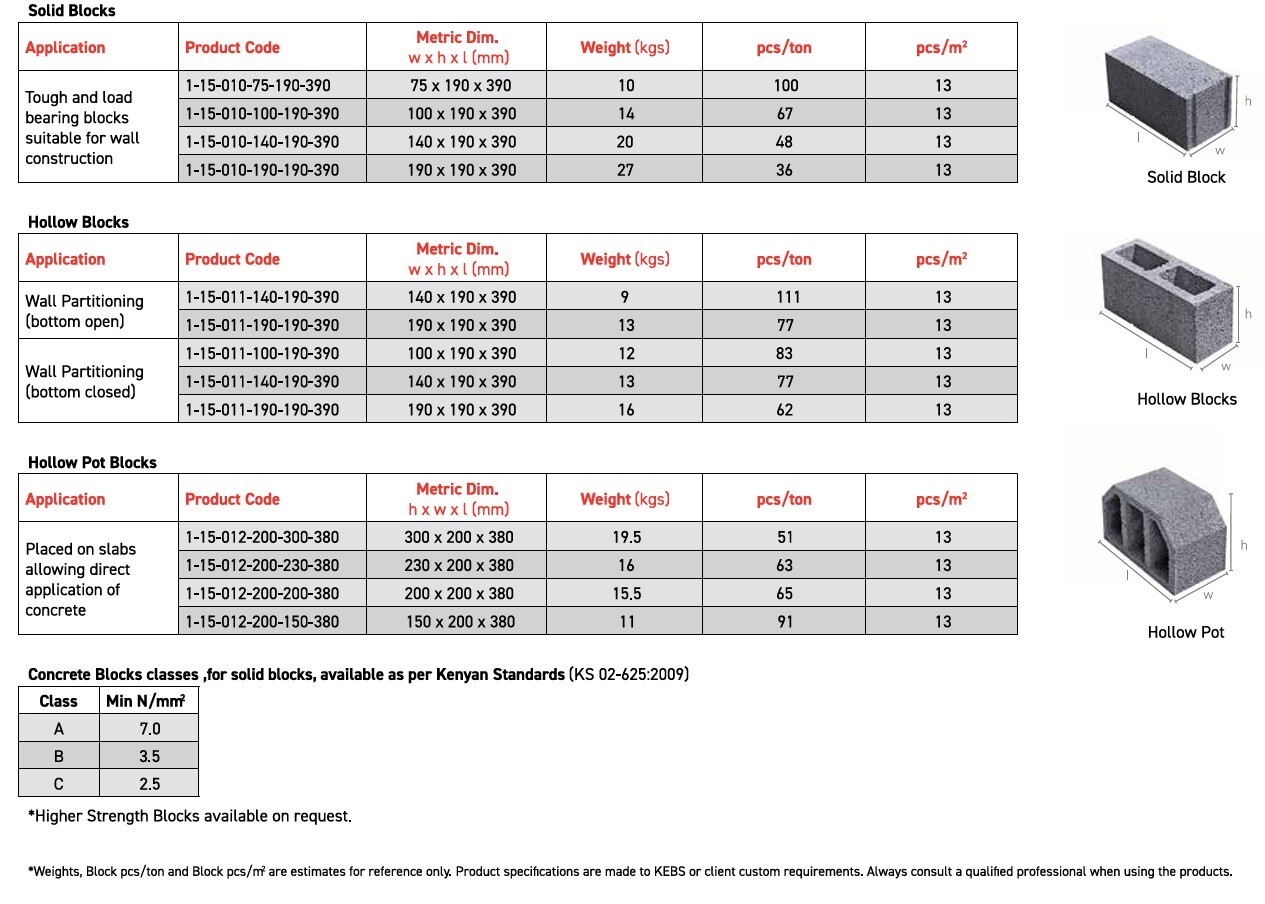

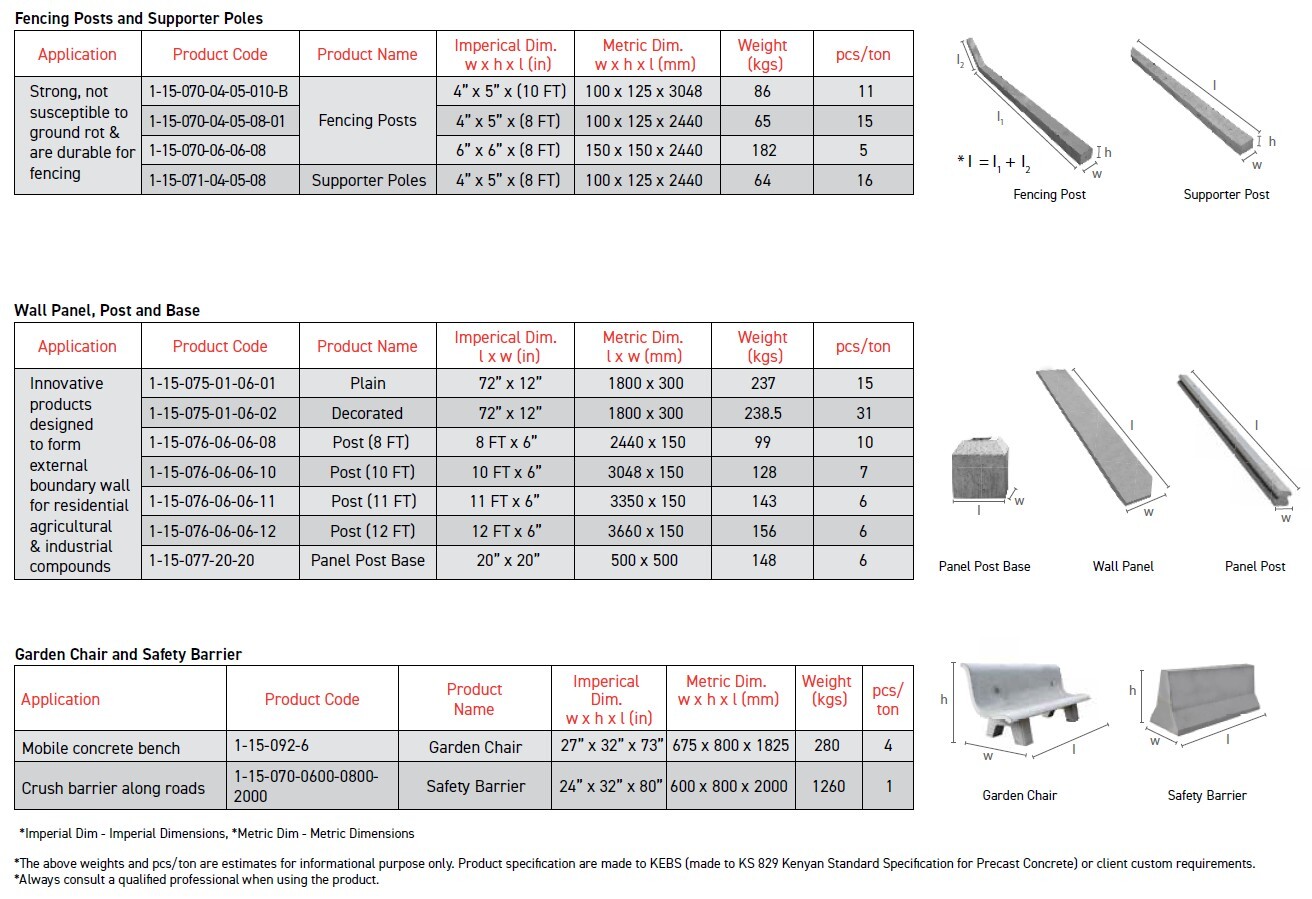

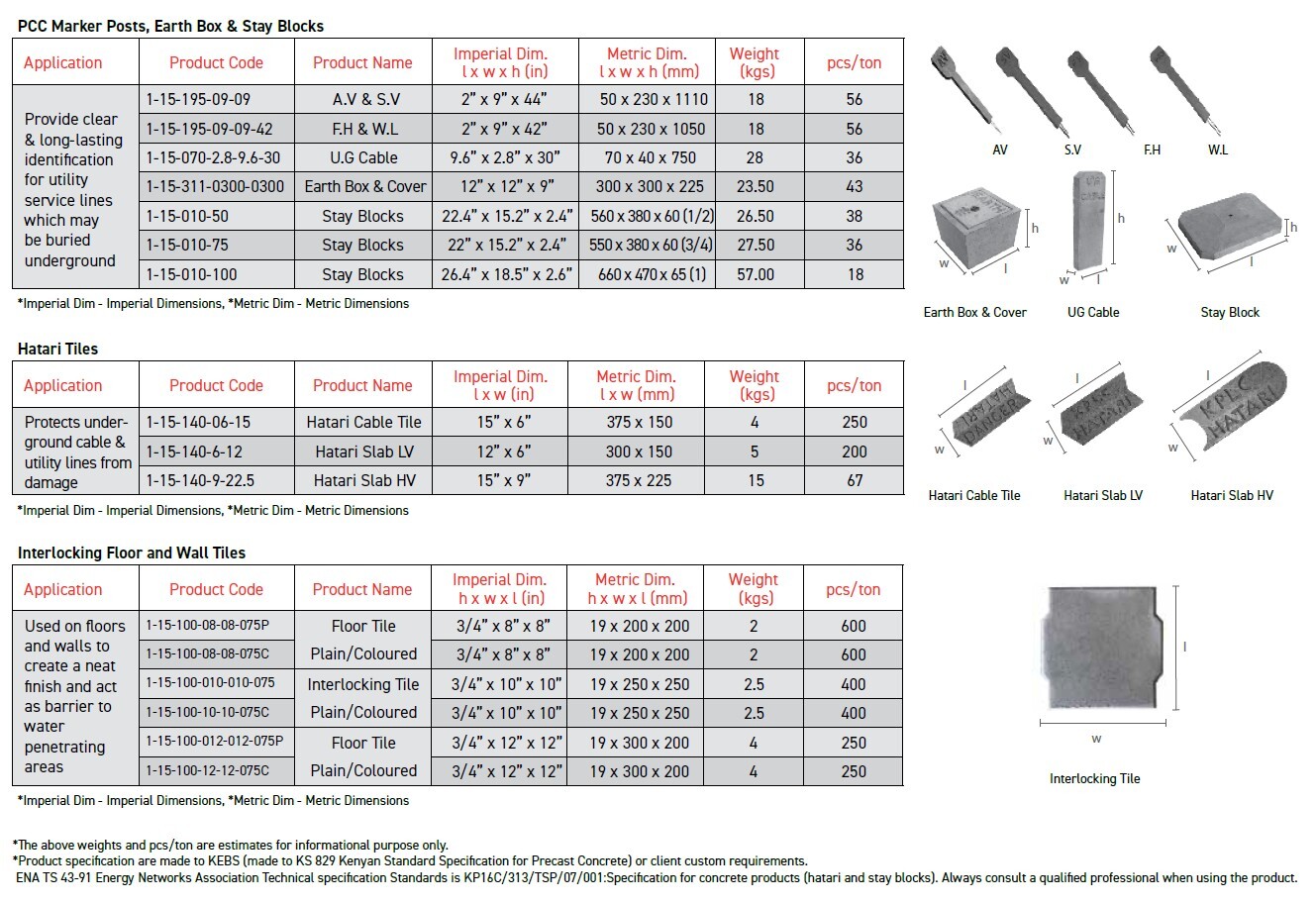

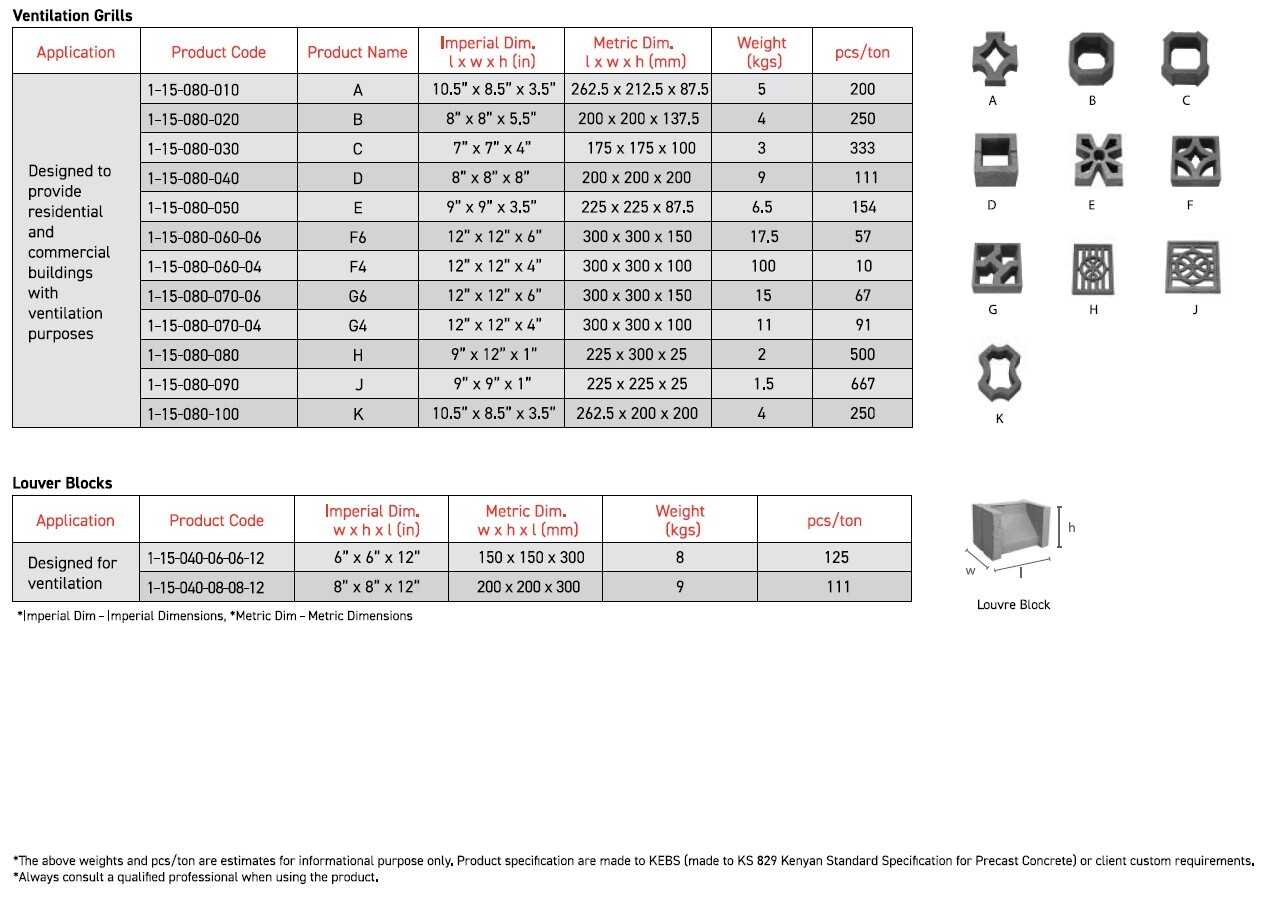

1. AGGREGATES FOR MANUFACTURE OF CONCRETE

Concrete Aggregates refers to the use of coarse materials such as gravel, crushed stone and recycled concrete in the manufacture of concrete. Essentially,

aggregate materials make up a large portion of the total volume of concrete and serve to enhance its overall strength.

FACTORS TO CONSIDER WHEN CHOOSING AGGREGATES FOR USE IN CONCRETE

1. Type of binder and cement characteristics such as gypsum or alkali content.

2. Total cementitious content.

3. Water-cement ratio.

4. Aggregate type.

5. Degree of hydration or cementing reaction.

6. Total water content in the fresh concrete.

7. Environment/exposure conditions of concrete.

8. Surface: volume ratio of the concrete as affected by shape and size of elements.

DIFFERENT CONCRETE APPLICATIONS

1. Foundations.

2. Suspended slabs.

3. Industrial & domestic floors.

4. Paths, patios & driveways.

5. Precast lintels, flagstones & blocks.

MATERIALS SPECIFICATION

1. When batching concrete, one should ensure that the aggregate does not contain any deleterious material (such as leaves, clay etc) as this can have a negative effect on the mix.

2. One should also be aware of the water content of the fine aggregates as this is very important in ensuring the control of cement content in the mix.

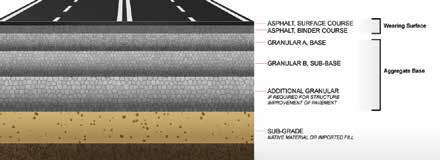

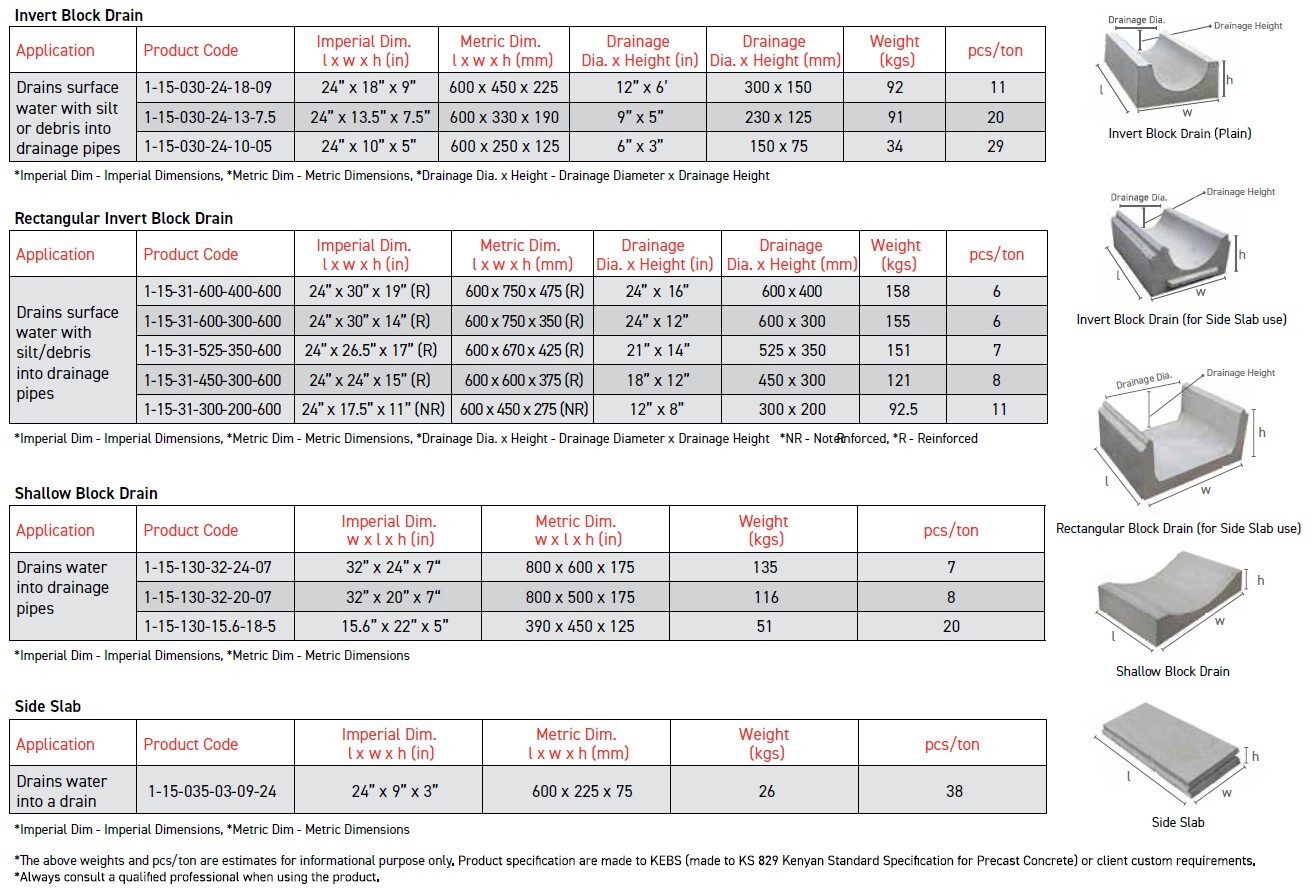

2. ROAD STRUCTURE LAYERS

Base and subbase materials provide the support structure for any pavement design.

Approved target gradings are determined by laying a trial section using material complying with grading limits as per the consultant's specifications.

The hardness and particle shape of aggregate used in road layer works is important as these influence workability, compaction and density achieved.

3. SURFACING AGGREGATE

Surfacing Aggregates are the aggregates used in the production of the surface layers or seals for road construction. These are usually applied by chip spreaders and comply with certain specifications.

The process involves spraying bitumen binder onto a prepared base-course layer and then applying aggregate particles immediately after and rolling them in to achieve a mosaic pattern. This causes the binder to move into the voids between the particles.

4. ASPHALT AGGREGATE

Asphalt Aggregates are those materials used in asphalt pavements. Asphalt is defined as a mixture of inert mineral matter, such as aggregate, mineral filler and bituminous binder in predetermined proportions. There are two types of Asphalt:

Continuously Graded Asphalts

These are mechanically mixed asphalts in which the aggregates and the filler are distributed in size from coarse to a fraction within a specific smooth grading envelope.

Open Graded Asphalts

These are mixes which normally require single-sized crushed aggregate. It is mechanically mixed asphalt constituted to give a rough surface texture in the compacted state. This type of layer is also used when ultra-thin pavement is laid using paving machines.

Due to the importance of aggregates in mix, it is vital to understand the impact its properties have on concrete consistency and to ensure the asphalt design mix meets the specified requirements.

/Single%20Crush%20Aggregate..jpg?width=700&name=Single%20Crush%20Aggregate..jpg)

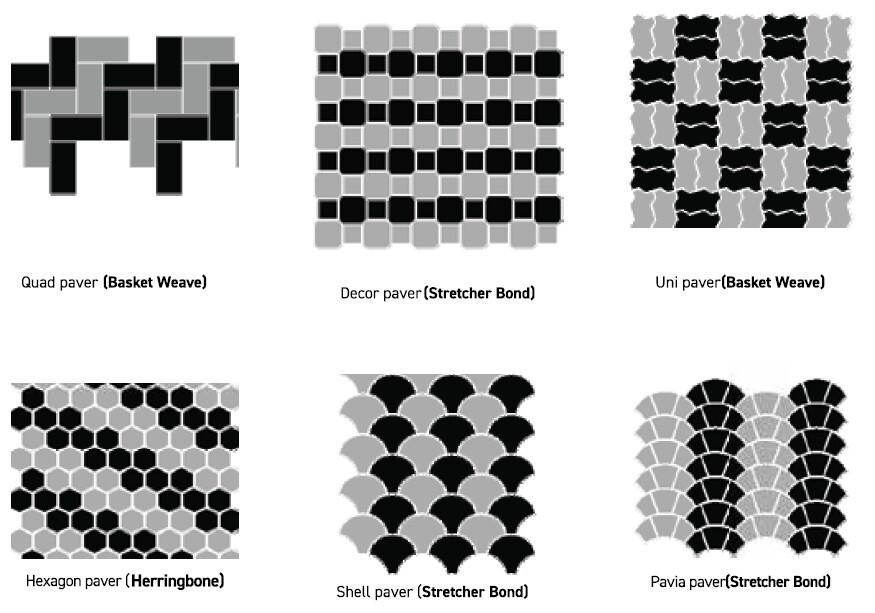

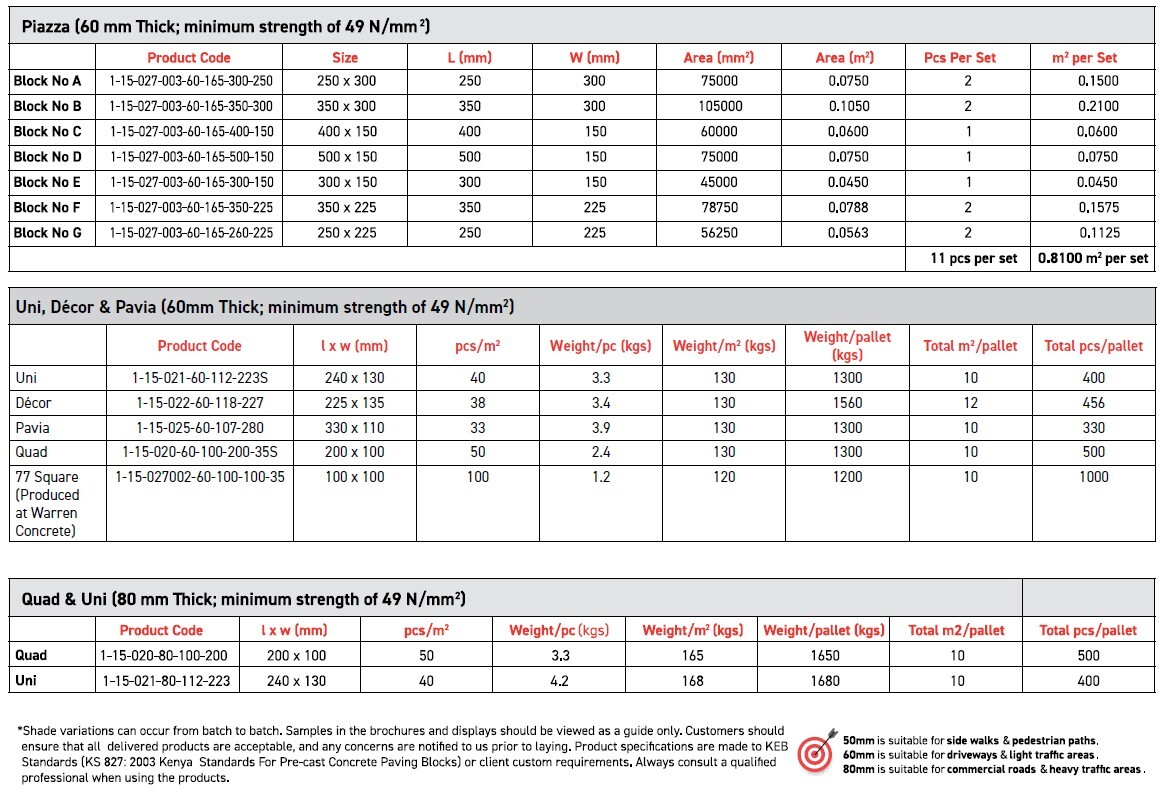

To achieve neat driveways and patios there are three laying patterns to consider which include Basket Weave, Herringbone and Stretcher Bond.

Stretcher bond is the simplest offset block paving pattern and is also known as a running bond or half bond. The joints are offset by exactly half the width of the block when using the quad paving block.

Herringbone is an interlocking laying pattern which is used for all tracked areas such as driveways. The interlock ensures that where vehicles are braking and turning, blocks are not moved out of position.

Basket weave pattern is commonly used on patio areas. As a decorative pavement it looks nice, however for heavy truck areas, basket weave is not recommended.

It is necessary to prepare subgrade and subbase so that the surface levels are within the tolerance. Preparation of the sub material provides a surface that is dense enough to prevent laying course material being lost into it during construction.

Should be adequate to support traffic loads and to prevent loss of laying course material beneath the surface course. Examples are kerbs and channels, established structures or rigid abutments such as paving blocks fixed vertically and bedded and haunched.

It is important to lay blocks and make minor adjustments to maintain the bond pattern and ensure that the joints remain wide enough for sand. Block paving is designed to function with sand joints, which will normally lie within the range of 1 – 1.5 mm when placed hand tight.

Use compacting equipment and transmit a frequency of vibration in the range 75 – 100 Hz. After compaction of the surface course, spread sand or crushed rock fines over the surface and brush it into the joints. Do not use sand which might stain pavement surfaces if this is an important consideration.

A properly designed, located and constructed concrete block pavement will perform well for many years. A combination of regular inspection and light maintenance will ensure long-term durability and performance.

Paving Blocks 80mm Quad, L*W (mm) 200*100, Pcs/sqm 50, Weight/pc (kgs) 2.1

1. REDUCES CONSTRUCTION COST

Using concrete block in construction significantly reduces cost in various ways. To produce clay brick, hectares of land, tons of wood and coal are wasted. If we practice using concrete block we can save these natural resources to build our home. Each block can save approximately 25% compared to using clay brick. Quarry cut stone requires large land masses for its extraction and once depleted become redundant sites resulting in further environmental damage.

2. REDUCE MAINTENANCE COST

In the long run, concrete buildings and pavements “stand the test of time” through their low maintenance requirements and have a significant sustainable advantage over other structures. Moisture, which can undermine other building materials through rust or rot, has no weakening effect on concrete. Neither termites nor mold take any toll on concrete. In fact, concrete continues to strengthen over time, which is why concrete structures built thousands of years ago are still intact.

3. EXTREMELY DURABLE

Concrete is one of the most durable materials on Earth. Concrete homes are far less likely to suffer damage in the event of earth tremors and earthquakes. Concrete blocks can be reinforced to protect against high winds or earth tremors. If damage does occur, the structural integrity of the home typically remains intact, allowing for easier rebuilding. Concrete block is unquestionably

the most practical home building material. There is no rotting or wall warping. Your home retains its appeal and its value beautifully.

4. ENERGY SAVER

Insulated concrete wall systems provide high R-value and thermal mass with low air filtration to provide superior thermal efficiency and optimal energy performance over the long life of the building. Since homes and buildings constructed with insulated concrete walls are not subject to large daily temperature fluctuations, owners can lower heating and cooling bills by up to 25%.

5. DESIGN FLEXIBILITY

Concrete block is an extremely flexible building material. Concrete block can be used to build just about any type of house feature imaginable. Columns, archways and other intricate designs are all easily achieved with the material. Building with concrete block means you have the flexibility to do just about anything you want, whether it be a one-storey home or a three-storey home with options such as high ceilings and tall windows. On the contrary, quarry cut stone cannot be easily altered and is difficult to repair or relocate.

6. SUSTAINABILITY

Concrete blocks are made from recyclable materials, hence reducing their impact on natural resources. On the contrary, clay bricks and quarry cut stones, once formed, are difficult to remold and reuse.

Wall Copping One Side Slope - 15" X 24"